PROCHARGER’S THERMAL ADVANTAGES

ProCharger is known for producing the largest, most repeatable power. Because of ProCharger’s product design advantages, the power that is seen on the dyno is also representative of the real world performance delivered at the track and on the street.

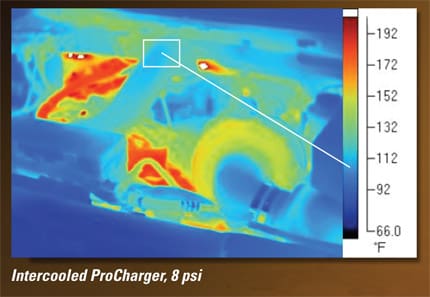

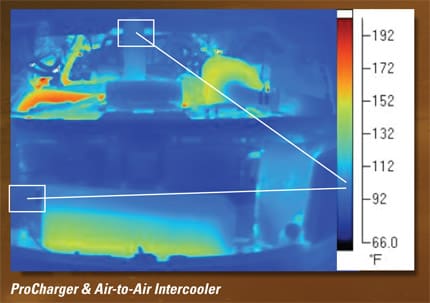

The above images show a ProCharged engine, with the top photo taken with a traditional camera to provide perspective when looking at the bottom image. The thermal image was taken following 3 dyno pulls, and helps illustrate the advantages of centrifugal efficiency and mounting location. Unlike other systems, the ProCharger system design locates both the supercharger and the intercooler away from the motor, avoiding the heat associated with engine top mounting or an exhaust interface. This advantage in mounting location, which limits heat transfer from the engine, improves peak output while also reducing exposure to detonation. The ProCharger advantage becomes even more clear when making back-to-back hits, without cool down time (thermal image below shows both ProCharger and Intercooler).

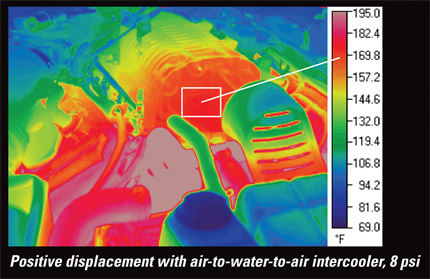

A competing manufacturer can flash a good dyno number in optimized conditions with a relatively cold motor, but this is not representative of real world use. The truth is that competing products not only produce less power to begin with, but suffer significant power fade due to differences in supercharger and intercooler technology, and their exposure to heat transfer within the engine compartment. Take a look at the thermal image below and the heat generated. This thermal image was taken on a vehicle with a PD blower after 3 dyno pulls, at the same boost level as the ProCharged engine. The thermal images speak for themselves – Cooler is Better.

POWERx3 is ProCharger’s thermal and performance advantages delivered by three primary design elements:

1. Supercharger Efficiency: ProCharger’s optimized centrifugal designs produce far higher compressor efficiency than positive displacement and screw superchargers. This means cooler air temperatures, and lower parasitic losses.

2. Intercooler Effectiveness: Experts Agree that air-to-air intercooling provides inherent cooling advantages for street use. Air-to-water intercooler systems for street use utilize a secondary front-mounted heat exchanger to cool the heated water, and are actually air-to-water-to-air intercoolers. This type of intercooling works well for racing, which can utilize ice and is only for a short burst, as well as for marine use, where the water under the boat acts as a massive radiator. However, for street use, air-to-air intercooling is superior in terms of both cooling and durability.

3. Engine Compartment Heat Transfer: Because centrifugals are typically mounted to the side of the engine in a fresh air stream, they operate much cooler than positive displacement blowers or turbochargers. During real world usage, the heat transfer from the engine to the blower (and intercooler) or turbo due to engine top mounting or an exhaust interface is significant. ProCharger’s self-contained oiling design is also advantaged relative to turbochargers and engine-oil-fed superchargers, as tests have demonstrated that ProCharger’s internal lubricating oil operates at a lower temperature than engine oil.

For more information on ProCharger’s largest power gains and coolest charge air temperatures, please follow the link, visit our website and check out this video.